UL1061 is designed specifically for temperature resistance and mechanical stability, with an operating temperature of 80°C making it suitable for most indoor environments. Semi rigid PVC material endows it with anti-wear and anti-aging properties, and is suitable for long-term fixed wiring or parts requiring slight movement (such as connecting wires near the motor shaft). In electrical equipment, it is often used as a control signal line or low-power power line, such as the connection between PLC modules and sensors, and the internal winding of small transformers. Its uniform insulation thickness ensures consistent peeling and has passed CSA FT1 combustion testing, meeting the stringent safety standards of North America. It is a reliable choice for scenarios such as medical equipment and office automation systems.

Feature

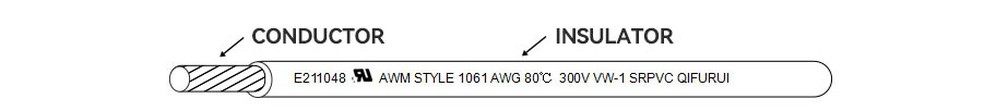

Condutor :Strands Tinned/Bare Copper

Insulation :SR-PVC

Reted Temperature:80℃

Reted Voltage:300Vac

Excellent thermal stability

Good flame retardancy

Electrical insulation good

Can be twisted pair and multi-core

Good processing properties Harness

Standard Reference:UL 758,UL1581

Environmental testing pass ROHS

UL 30awg to 14awg

Structure

Colors Available: BLACK, WHITE, RED, YELLOW, GREEN, BLUE, BROWN, GREY, ORANGE, VIOLET

Our Service

Corporate vision

Become a world-renowned supplier of electronic components, providing customers with satisfactory electronic solutions.

3F concern

High temperature resistance, high pressure resistance, ultra-thin, environmental protection.

Social responsibility

Make our users products safer. Save resources and make the planet we live in a better and more harmonious place.

Quality policy

Quality first, delivery guarantee, active service, customer first, step by step, zero defect management.

Partners

FAQ

Q:1.What is the delivery time for mass production?

A:Production lead time: 20~30 days.

Q:2.What is your terms of delivery?

A:We accept EXW, FOB, CFR, CIF. You can choose the one which is the most convenient or cost effective for you.

Hot Tags: UL1061, China UL1061 suppliers, manufacturers, factory, stainless ties, auto wiring cable, yellow cable ties, insulate pex pipe in attic, gold cable ties, basic auto wiring

Technical Parameters

|

STYLE

|

SIZE AWG

|

Conductor construction (No./ mm) ±0.005

|

Conductor resistance 20℃ (Ω/Km)

|

Conductor diameter (mm)

|

insulation thickness (mm) |

Over diameter (mm) |

||

|

Nom. |

Min. |

Nom. |

Tole. |

|||||

|

|

14 |

41/0.254 |

8.96 |

1.90 |

0.35 |

0.26 |

2.60 |

±0.15 |

|

16 |

26/0.254 |

14.60 |

1.50 |

0.35 |

0.26 |

2.20 |

±0.1 |

|

|

18 |

16/0.254 |

23.20 |

1.17 |

0.25 |

0.18 |

1.65 |

±0.1 |

|

|

20 |

21/0.18 |

36.70 |

0.95 |

0.25 |

0.18 |

1.45 |

±0.1 |

|

|

10/0.254 |

36.70 |

0.93 |

0.25 |

0.18 |

1.43 |

±0.1 |

||

| 22 |

1/0.65 |

56.40 |

0.65 |

0.25 |

0.18 |

1.15 |

±0.1 |

|

|

7/0.254 |

59.40 |

0.77 |

0.25 |

0.18 |

1.26 |

±0.1 |

||

|

17/0.16 |

59.40 |

0.76 |

0.25 |

0.18 |

1.26 |

±0.1 |

||

|

24 |

7/0.20 |

94.20 |

0.61 |

0.25 |

0.18 |

1.10 |

±0.1 |

|

|

11/0.16 |

94.20 |

0.61 |

0.25 |

0.18 |

1.10 |

±0.1 |

||

|

26 |

7/0.16 |

150.00 |

0.48 |

0.25 |

0.18 |

0.98 |

±0.1 |

|

|

28 |

7/0.127 |

239.00 |

0.38 |

0.25 |

0.18 |

0.88 |

±0.1 |

|

|

30 |

7/0.10 |

361.00 |

0.31 |

0.25 |

0.18 |

0.81 |

±0.1 |

|